Steel fibers typically require special conveyors or extra man-hours to add to a concrete mix. Steel mats or rebar are very labor intensive to place on chairs and supports and to tie properly. MiniBars macro synthetic fiber can be placed with a laser-guided screed and can eliminate the need for a concrete pump in these situations. MiniBars benefits projects by reducing labor hours and placement time, providing significant job savings.

High compatibility between materials increasing fiber bond

Surface RoughnessPhysical bond & friction

Helical ShapeMechanical anchorage increasing pull-out resistance

MiniBar™ Bond and Pull Out resistance in Concrete

MiniBars™ have 4 bond/pull out resistance mechanisms to take advantage of the elastic material properties

Broken specimen with higher dosage than 10 Kg/m3 – 17 lbs/yd3

High-Strength MacroFiber

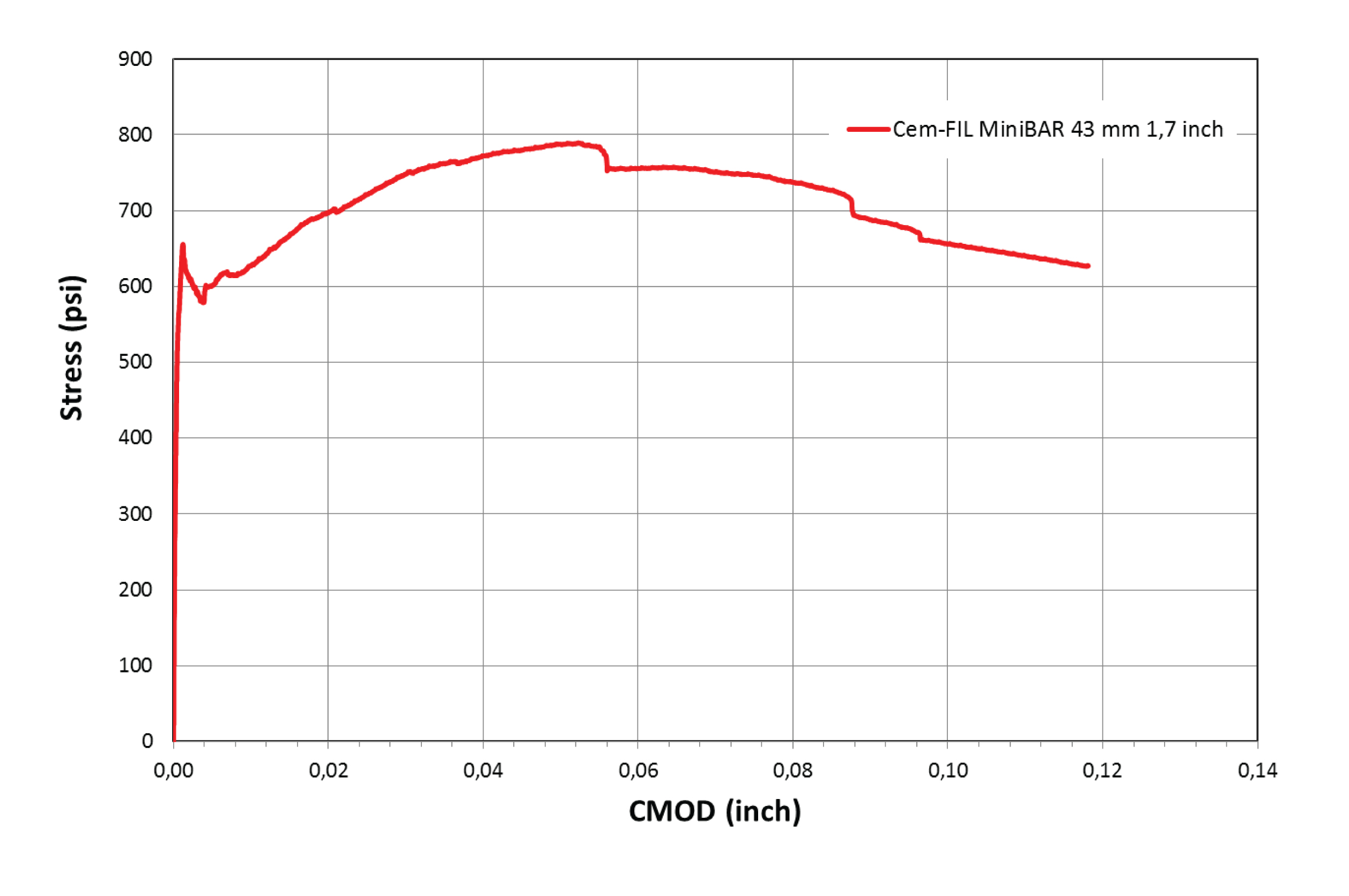

| Fiber Type | MiniBars™ 43mm | 1.7” |

|

| MPa | psi | |

| Maximum Load | 5.4 | 789 |

| fl | 4.5 | 656 |

| fR1 | 4.6 | 673 |

| fR3 | 5.1 | 740 |

| ARS | 4.9 | 709 |

Flexural Tensile Strength

MiniBars™ @10 Kg/m3 (17 lb/yd3) in a 50 MPa concrete (7250 psi) According to EN 14651 Specimen: 10x10x50 cm (4x4x20 in) | Span= 350 mm (14 in)

| Concrete Type | Reference | +10 Kg/m3 – 17 lbs/yd3 MiniBars™ |

Reference | +10 Kg/m3 – 34 lbs/yd3 MiniBars™ |

| Slump | Flow | |||

| C30/37 4400 psi |

180 mm 7.1 in. |

160 mm 6.3 in. |

- | - |

| C70/85 10200 psi Self-leveling |

- | - | 540 mm 21.3 in. |

510 mm 20.1 in. |

This unique combo of high performance MiniBars™ and Basbars™ has plenty to offer.

Lightweight

Working with fiber is a breeze. It is only a quarter the weight of steel. This makes a world of difference for your crew.

Faster Completion

Because they are easier to work with, projects get completed at a faster rate.

Less Material

With fiber, less concrete is needed; producing lighter panels and thinner panels.

Lower Costs

When less material is used, logistics and construction costs are reduced.

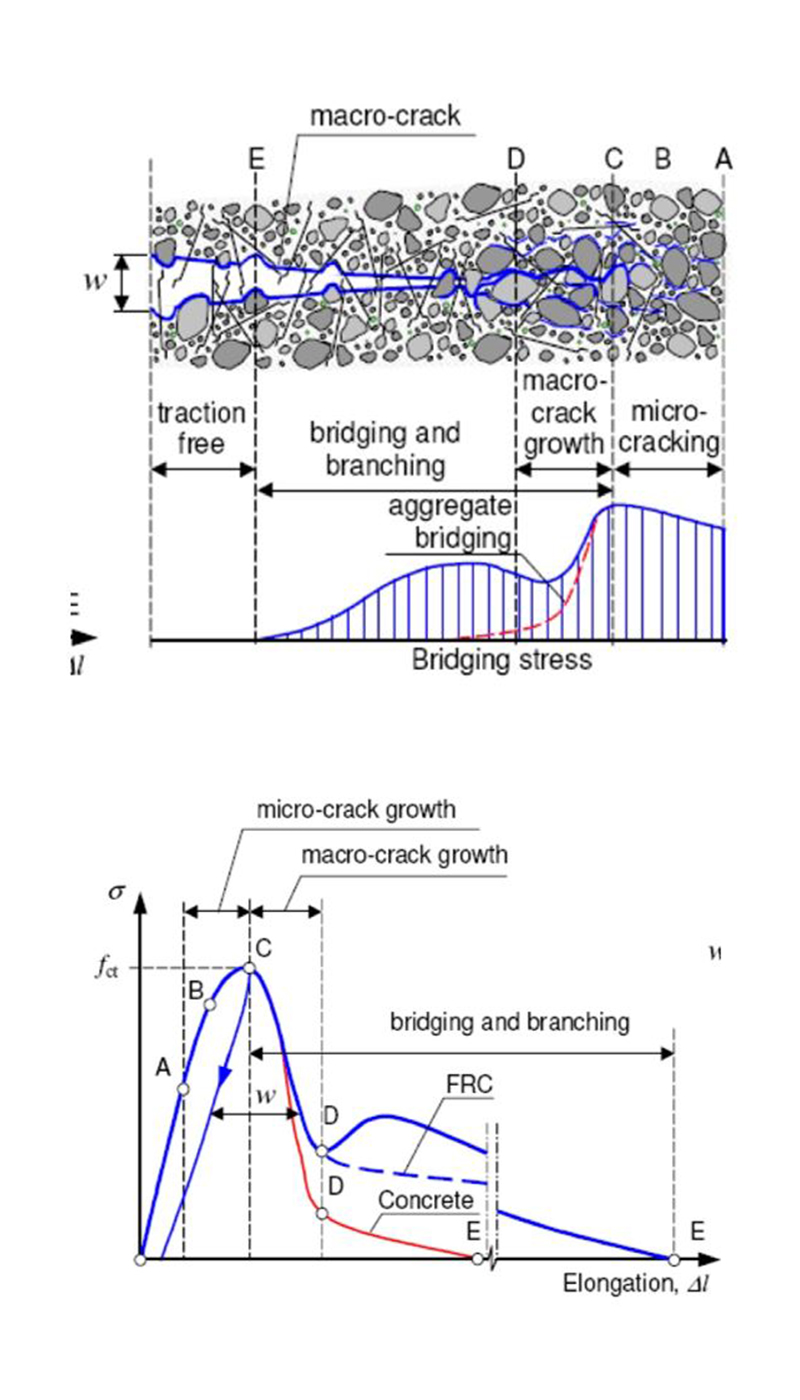

Because MiniBars™ have a density close to concrete, they disperse swiftly and evenly when mixed in concrete; creating a network of randomly placed fibers throughout the concrete. As load is applied to the concrete the MiniBars™ act as crack control and distribute the load throughout the beam.

2.4

Concrete2.0

MiniBar™7.8

Steel0.9

Polypropylene

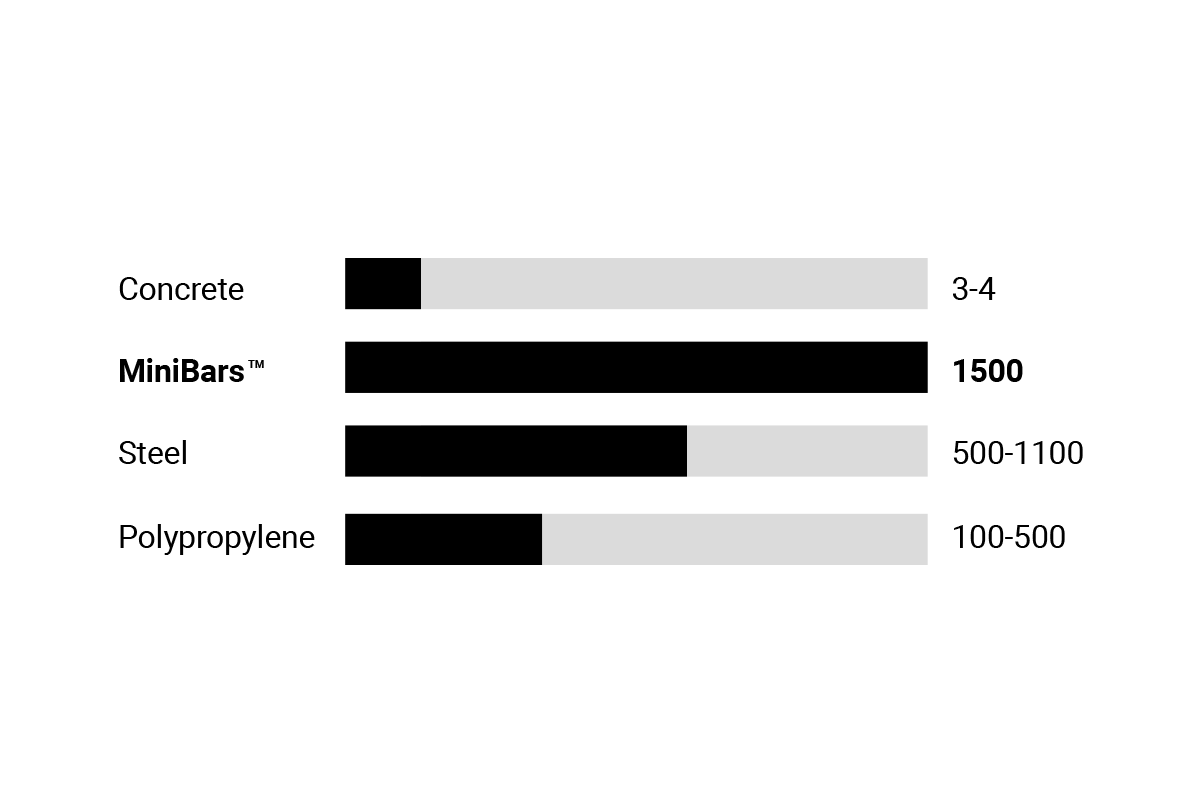

MiniBars™ possesses a tensile strength twice grater than steel

It Is Versatile

Our reinforcement composites are a blend of mineral fibers, they can be manufacture to meet an array of requirements. Designers are free to create exciting new products and, in many cases, are only limited by their imagination. MiniBars™ reduce or replace secondary and or primary steel reinforcement in many structural applications requiring flexural tensile and post-crack performance.

Non-conductive

Perfect for building electronic test facilities and such

Zero corrosion

Solves corrosion problems in marine structure such as bridges and pontoon

Non-magnetic

Great for applications in road and railways for trams or electric buses

LESS COST

33% Less Costs

Less concrete is needed and zero need for steel

LESS MATERIAL

40% Less Labour

Lower weight lesser burden lesser labour

LESS EVERYTHING

37% Less Time

Faster project completion

| Totals savings of 30% | Steel Net | MiniBars™ |

| Reinforcement | 100% | 10% Higher |

| Form Work | 100% | 100% |

| Bar or Net Fixing | 100% | 100% saved |

| Stool or Chair Fixing | 100% | 100% saved |

| Concrete | 100% | 20% saved |

| Comparative Costs | 100% | 67% |

Surprising Lightness

MiniBars™ provide strength and versatility, with surprising lightness and durability.

Low weight (density 1/4 of steel) enableseasy handlight manufacturing plant or construction site

Reduced concrete cover layer eneblesless concrete weight and lighter structures

Solutions for pre and post-tensioning

Simplicity

Mineral fiber concrete reinforcement eliminates the need for steel and wire mesh. Working with steel is a hassle. Working with fiber is a breeze. It is only a quarter the weight of steel.

Light Weight

Because mineral fiber is only a quarter the weight of steel, this makes a world of difference for your crew

Faster Completion

Because they are lighter, thus they are easier to work with, making it possible for your construction to get completed at a faster rate.

Less Material

With fiber, less concrete is needed producing lighter panels and thinner panels.

Lower Costs

When less material is used, logistics and construction costs are reduced.

Lean

Thinner panels also makes slenderer buildings. Better looking aesthetics and larger inner space.

Eco Green Environment

When less material is used, carbon footprint on the environment is reduced too.

Design Freedom

They also increase your design freedom, making thinner panels for a slenderer building. Better looking aesthetics and larger inner space.