| CHARACTERISTIC | MINIBAR BASALT |

|---|---|

| MATERIAL PROPERTIES | |

| Base Resin | Epoxy Resin |

| Tensile Strength (Minimum) | > 900 Mpa |

| No. of Fibers Per KG | 28 850 /Kg |

| Specific Gravity | 2.1 |

| Youngs Modulus | 42 |

| Melting Point | Not Known |

| Ignition Point | 410 ºc |

| Softening Temperature | 104 ºc |

| Packaging Size | 10 Kg Per Box |

| ackaging Dimensions Per Box | 38cm(L) x 39cm(W) x 50cm(H) |

| Length(I) | 20, 30, 43 & 55mm |

| Nominal Diameter (d) | 0.72mm |

| Aspect Ratio (I/d) | 30, 40, 60, 80 |

Introducing Basalt

Basalt Fiber is a new material fiber made from natural stone material. Basalt is non corrosive natural and it will not deteriorate or rust like iron.

Basalt fiber the next-generation industrial material with characteristics similar to carbon fiber, and is expected to be used in automobile-related industries, vehicle / aircraft-related industries, civil engineering and construction-related industries, infrastructure life extension work, etc.

Basalt fiber is environmentally friendly because it will not deteriorate and can be disposed easily with a general incinerator.

Basalt fiber has excellent radiation resistance and is suitable as a material for interim storage facilities such as contaminated soil and decommissioning work in areas affected by nuclear disasters.

Basalt fiber has excellent heat resistance and is suitable for non-combustibility measures in densely built-up areas.

Basalt fiber is non-conductive and is suitable as a seismic material for tunnels

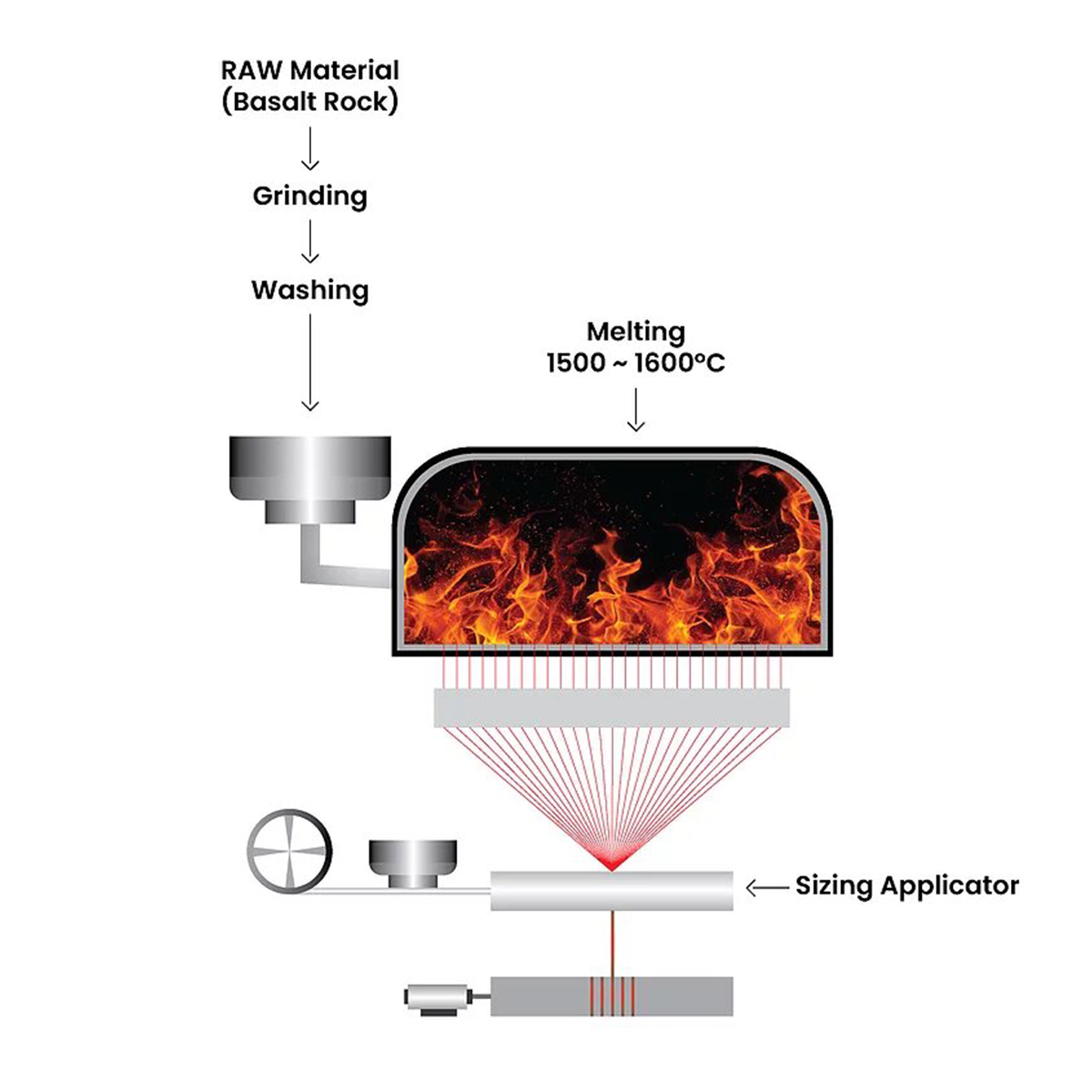

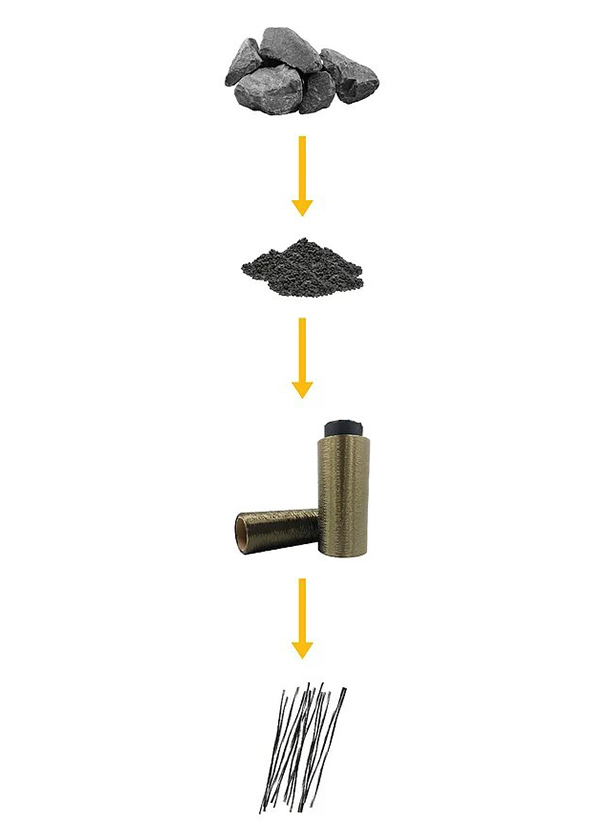

Process of Basalt stone to Basalt MiniBars

MiniBars™ fiber disperses quickly and evenly throughout the concrete matrix, due to its specific gravity being similar to concrete

This inherent characteristic of composite glass fiber ensures the expected fiber performance throughout the concrete mass

| Material | Specific Gravity | Elastic Modulus (GPa) | Tensile Strength (MPa) |

|---|---|---|---|

| Concrete | 2.4 | 30-40 | 3-4 |

| MiniBar | 2.0 | 42 | 1500 |

| Steel | 7.8 | 210 | 500 - 110 |

| Polypropylene | 0.9 | 1.5 - 9.5 | 100 - 500 |

MiniBars has the best of both Synthetic and Steel fibers

| Fiber Type | Synthetic | Minibars | Steel |

|---|---|---|---|

| Tensile Strength Mpa | 465 | 1100 | 1100 |

| Volume per kg | 38000 | 28000 | 2800-5200 |

CEM-FIL AR GLASS MINIBARS

AR Glass MiniBars are made from Owens Corning Cem-Fil Fibers formed into a unique helical twist shape.

Certifications

Our Project

Innovative Applications

with AR Glass MiniBars™

Cem-Fil© MiniBars™ for structural applications made from AR Glass fibres